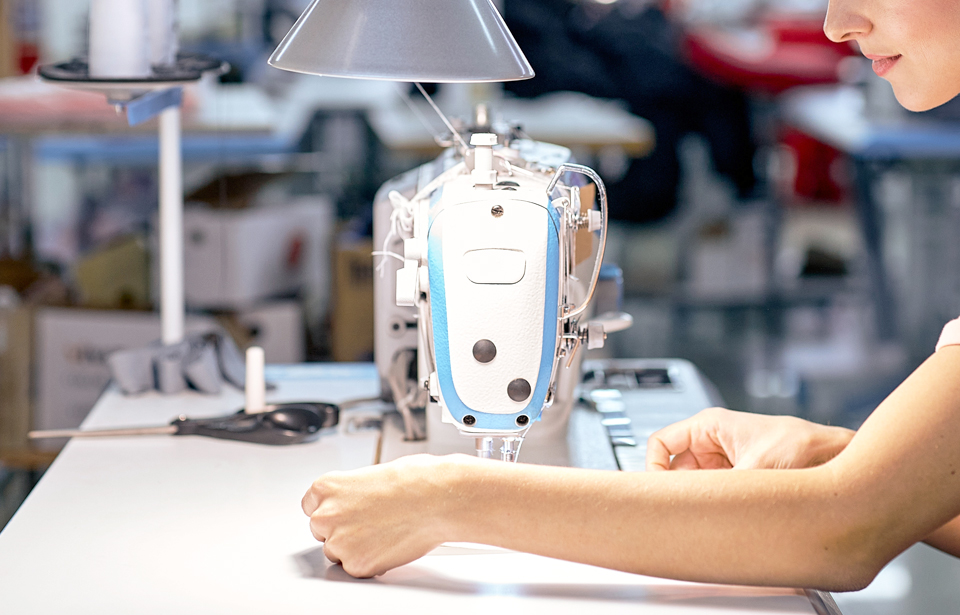

Manufacturing

We listen to your criticism and findings during the sample preparation process and transfer them to our production lines. We use state of art machines to check the fabrics we will use for the ready-to-wear knitted garments you order for children, men or women, and cut them off with minimum waste. We design each product development experience especially at our factory having a capacity to manufacture approximately one million products per month, and develop good textile manufacturing practices respecting the environment and the people. Our Cutting Inspection, Quality Assurance and Social Compliance departments formed by specialist teams work actively in the field to ensure the inspection and management works and applications to comply with our final targets in terms of operational excellency.

Quality

Efficient quality management system. Our top priority target is to integrate investments in advanced technology with our quality standards to meet the expectations and to ensure one hundred percent customer satisfaction. In order to perform all processes before and after the order stage in an efficient way, our physics and chemistry laboratories accredited by our customers and our competent Quality Assurance team manages the manufacturing process in accordance with the product quality specifications and the relevant standards in a sustainable way.

Quality

Efficient quality management system. Our top priority target is to integrate investments in advanced technology with our quality standards to meet the expectations and to ensure one hundred percent customer satisfaction. In order to perform all processes before and after the order stage in an efficient way, our physics and chemistry laboratories accredited by our customers and our competent Quality Assurance team manages the manufacturing process in accordance with the product quality specifications and the relevant standards in a sustainable way.

Our Certificates